Composites

1IC

Layer

2IC

Zone

3IC

Cast Composites

Product

1IC Composite layers reinforced with WC particles and are created using reactive liquid coatings in the traditional casting process. Thanks to its liquid consistency, you can use this solution to protect complex and complicated surfaces of your product. It is adapted to protect against medium and low abrasive wear and corrosion. For example, the application of the technology can be used for the protection of pipes, pump bodies, impellers in water or slurry environments, brake discs or parts for clinker coolers and for waste incineration. Reactive liquid foundry coatings can also be used as additional protection of wear. parts as a complement to 2IC solutions, e.g. the upper part of cone crusher mantles, the lower wear area of VRM roller tires, etc. Hardness up to 900 HV1, thickness from 0.5 to 3.5 mm of reinforced particles.

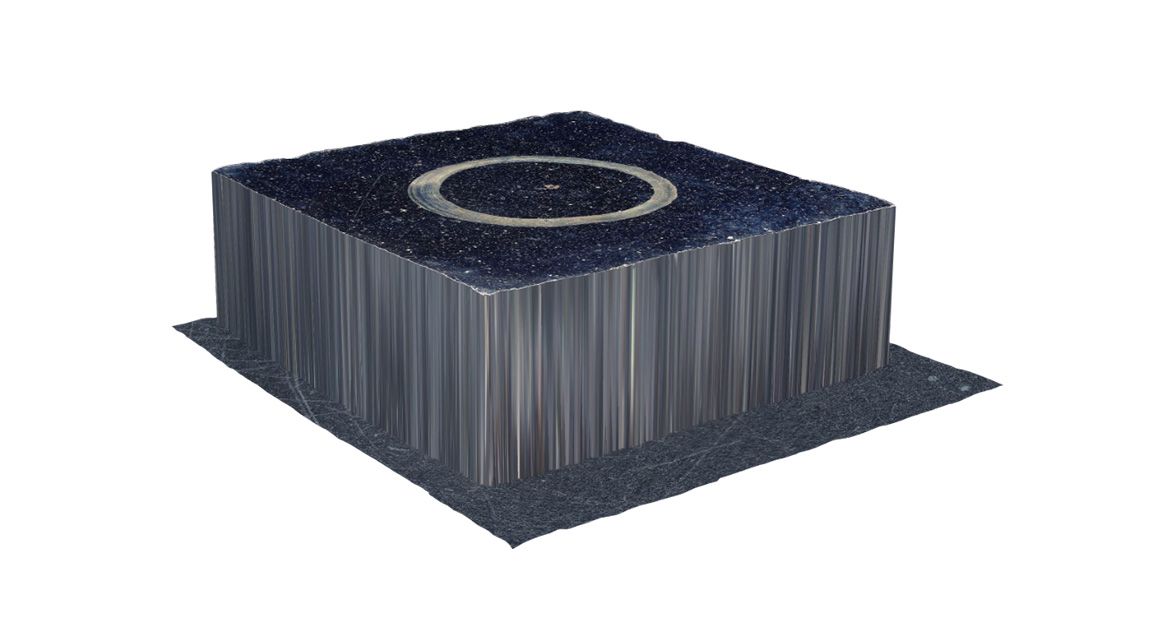

License

Innerco offers licenses for technologies from the InnerComposites (IC) family used to produce local composite reinforcements in casting products based on iron alloys, i.e. cast steel and cast iron. They allow strengthening with hard ceramic particles of the casting in its top layer – 1IC or adapted to the wear profile zone – 2IC. Both technology variants together provide ultra-high abrasion resistance. We are in the final stages of developing the final member of the family, cast composites – 3IC, in which reinforcing particles are distributed throughout the casting capacity. This form of partnership is complemented by a full range of services related to the technology transfer process and the ability of the Innerco team to execute the full new product development cycle.

The common feature of the InnerComposites technology family is the formation of reinforcing particles directly in the liquid casting melt, thus ensuring the highest possible quality of the resulting metal matrix composite material. Our offer is addressed to global market leaders in the production and/or service of machinery and equipment and vehicles, dedicated to the mining, cement, energy, recycling,

metallurgical, rock and mineral processing, agricultural, automotive and chemical industries – as well as supplying wear parts. The following is a general overview of the InnerComposites 1IC, 2IC and 3IC technology family.

Questions and technical support: +48694474547 | Send message

The general characteristics of the

InnerComposites 1IC family are presented below.

1IC Composites

1IC – Composite layers reinforced with WC particles are created using reactive liquid coatings in the traditional casting process. Thanks to its liquid consistency, you can use this solution to protect complex and complicated surfaces of your product.

It is adapted to protect against medium and low abrasive wear and corrosion. For example, the application of the technology can be used for the protection of pipes, pump bodies, impellers in water or slurry environments, brake discs or parts for clinker coolers and for waste incineration. Reactive liquid foundry

coatings can also be used in the standard protection of wear. parts as a complement to 2IC solutions, e.g. the upper part of cone crusher mantles, the lower wear area of VRM roller tires, etc. Hardness up to 900 HV1, thickness from 0.5 to 3.5 mm of reinforced particles.

Wear resistance*,

(wear index *10-9

[um3/Nm])

- Flake grey cast iron

- Innerco WC MMC

Median Vickers

hardness, [HV1]

- Innerco WC MMC

- Flake grey cast iron

Key features

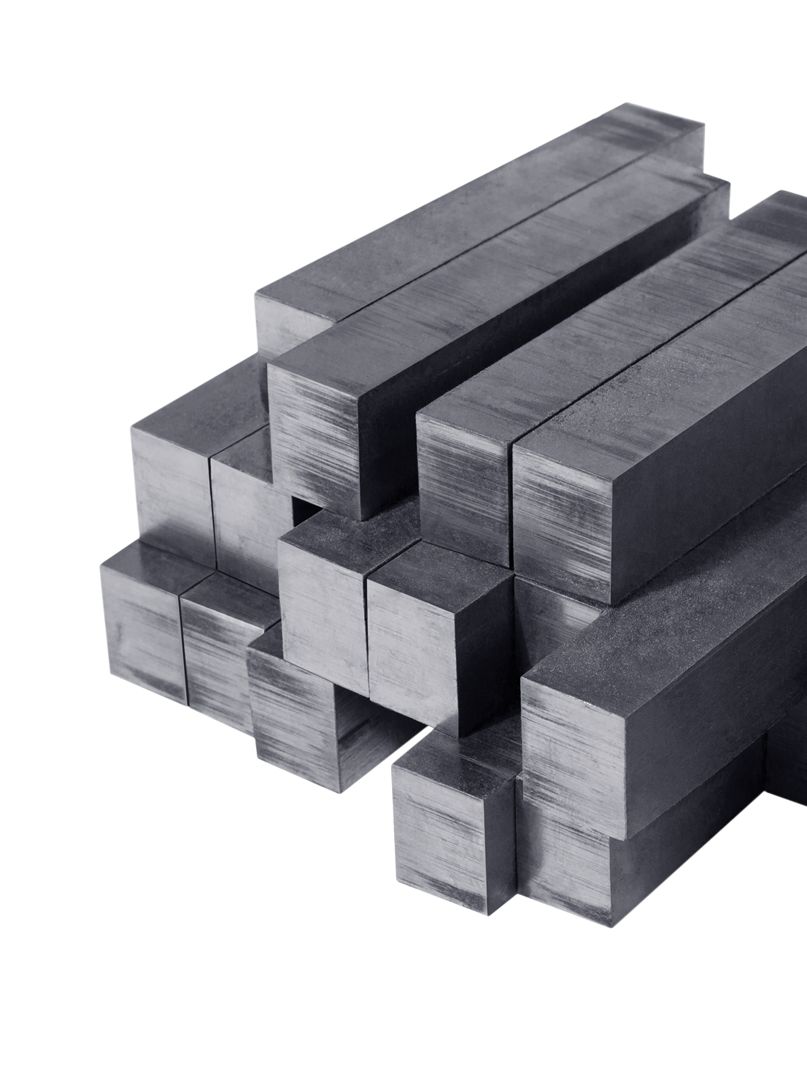

Castings

Standard casting vs high-functionality MMC castings

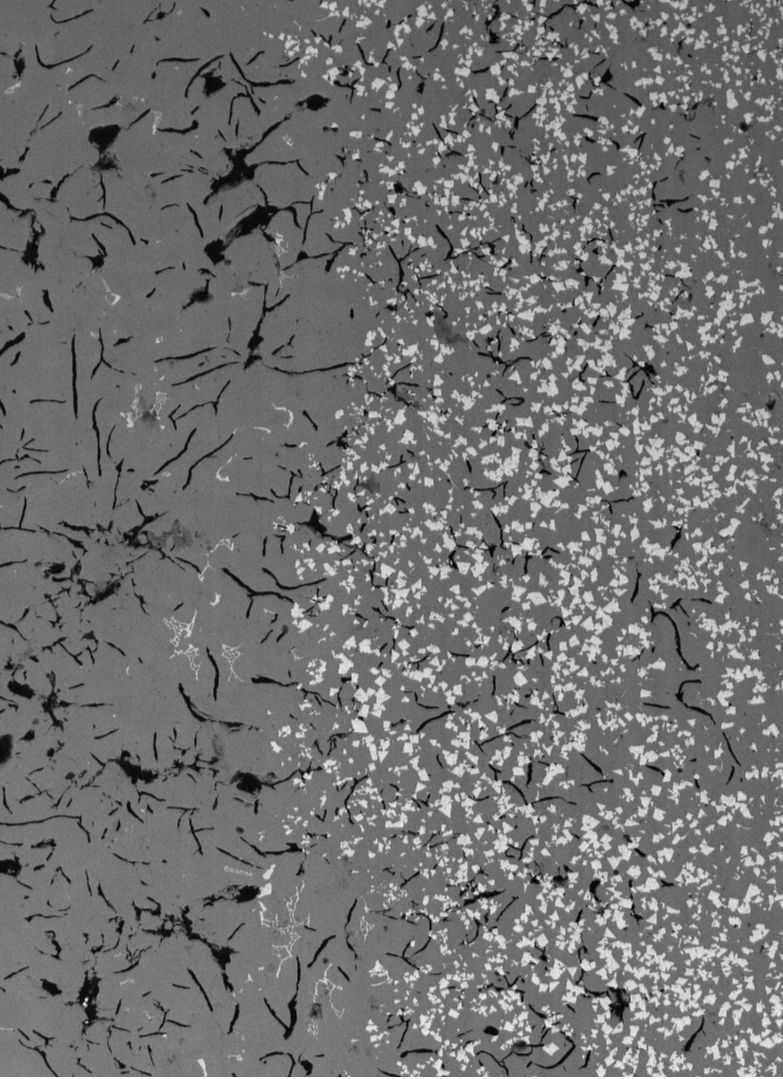

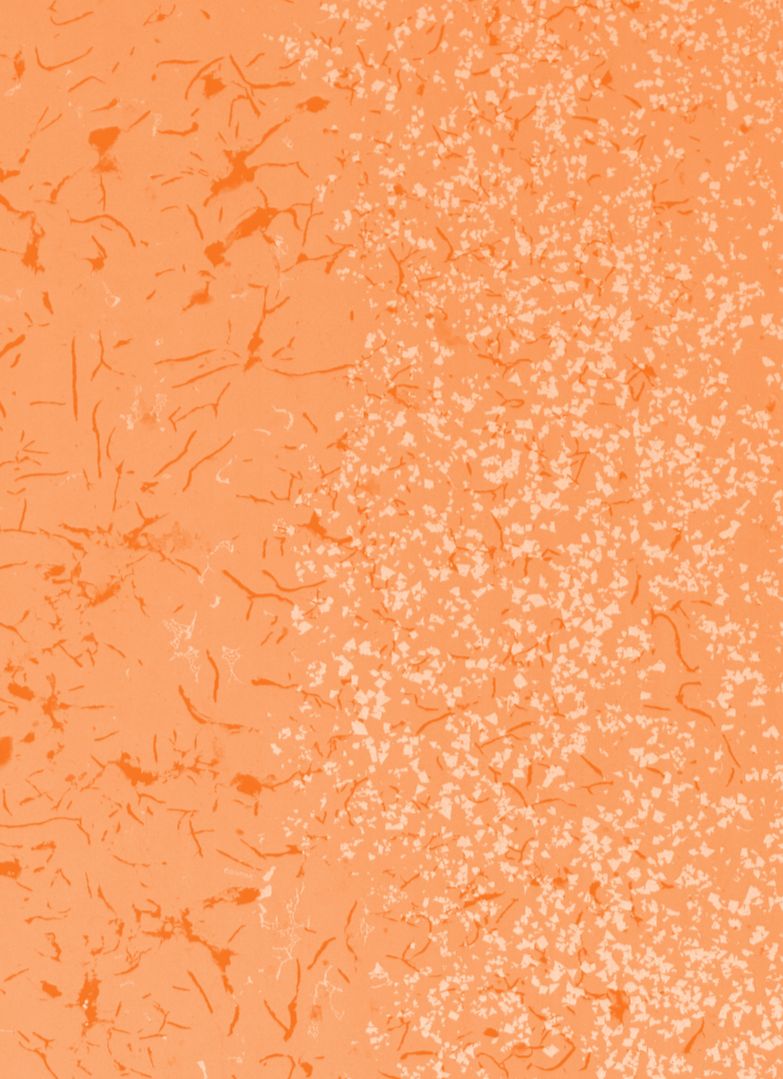

Laboratory

We are constantly developing new technologies to produce metal matrix composites in castings. Our laboratories test and analyse new materials’ mechanical, functional, and physical properties. We have access to apparatus, machinery and devices that allow for their full characterisation. In addition, in advanced research techniques, Innerco closely cooperates with leading research units in Poland, ensuring the highest quality and efficiency of research.

Manufacturing

1IC – Composite layers reinforced with WC particles are created using reactive liquid coatings in the traditional casting process. Thanks to its liquid consistency, you can use this solution to protect complex and complicated surfaces of your product. It is adapted to protect against medium and low abrasive wear and corrosion. For example, the application of the technology can be used for the protection of pipes, pump bodies, impellers in water or slurry environments, brake discs or parts for clinker coolers and for waste incineration. Reactive liquid foundry coatings can also be used in the standard protection of wear.